In the construction sector, seal strips are vital for maintaining the integrity of buildings and structures. They are used in windows, doors, and siding to prevent air leaks, which improve energy efficiency. Moreover, seal strips help in acoustical insulation, reducing noise transfer between rooms and enhancing comfort levels. For manufacturers, ensuring that their seal strips are weather-resistant and durable is essential, as these products are often exposed to harsh environmental conditions.

Weather strip foam seal is a type of insulation product commonly used to seal gaps and cracks around doors, windows, and other areas of the home where air may escape or enter. Made from various materials, including polyurethane, rubber, or vinyl, foam seals are designed to be flexible, allowing them to form a tight seal against irregular surfaces. This adaptability ensures that homeowners can address a range of issues, from small drafts to larger gaps, effectively.

Another vital benefit of door sponge seals is their ability to minimize noise pollution. In urban environments or busy commercial areas, unwanted sounds can be disruptive and stressful. By installing a sponge seal around doors, sound transmission is reduced, making spaces quieter and more conducive for work or relaxation. This is particularly beneficial in settings such as offices, hospitals, and homes with young children or noise-sensitive individuals.

Waterproof rubber seal strips may seem like a small component, but their significance cannot be overstated. They are a critical element in improving energy efficiency, protecting against moisture, and ensuring the longevity of various applications. Companies that manufacture these seal strips are at the forefront of innovation, quality, and sustainability, driving the industry forward.

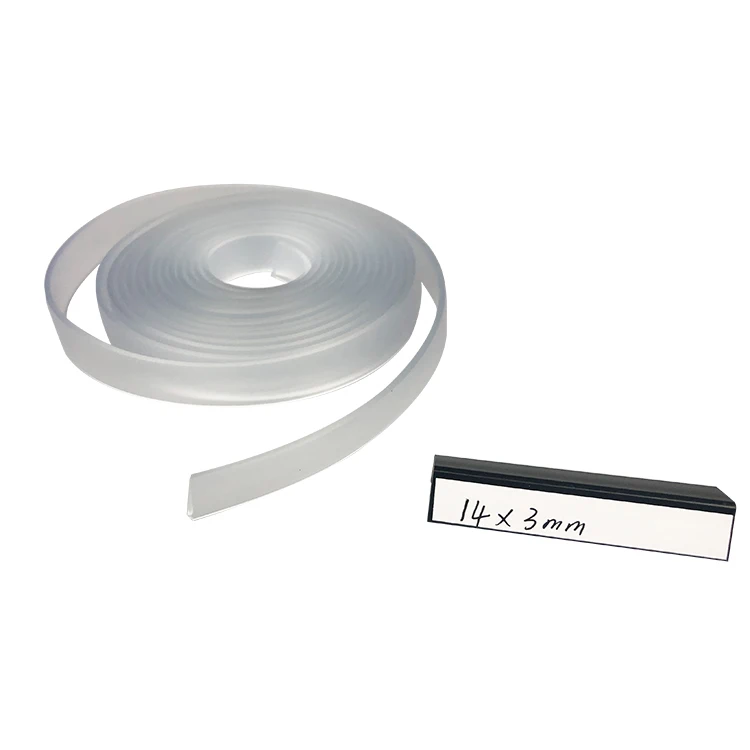

The benefits of utilizing thin and flat transparent silicone strips are numerous. Firstly, their flexibility allows them to be cut into various sizes and shapes, catering to specific needs. Secondly, the non-toxic nature of silicone ensures safety in applications, particularly in food and medical uses. Moreover, these strips are easy to clean and maintain, adding to their longevity and practicality.

1. Material Selection The type of material chosen for window seal strips is crucial. Common materials include rubber, silicone, and foam. Each of these materials offers different levels of acoustic insulation, flexibility, and durability, which are considered in the design phase. For soundproofing, high-density rubber and specialized acoustic foam are often preferred due to their superior sound-absorbing properties.

2. Enhanced Aesthetics A shower screen is often one of the focal points in a bathroom, and a custom seal strip can complement the design seamlessly. With a myriad of colors, styles, and materials available, you can choose a seal strip that not only fits perfectly but also matches your overall bathroom decor. This attention to detail can elevate the look of your bathroom, making it more inviting.

धातु वी पट्टी मौसम सील, या जिसे सामान्यतः व्ही-सील कहा जाता है, एक महत्वपूर्ण उत्पाद है जो भवनों और वाहनों में उपयोग किया जाता है। यह सीलिंग समाधान न केवल तापमान को बनाए रखने में सहायक होते हैं, बल्कि धूल, पानी और अन्य तत्वों से सुरक्षा भी प्रदान करते हैं। इस लेख में, हम धातु वी पट्टी मौसम सील के निर्यात के महत्व और इसकी वैश्विक मांग पर चर्चा करेंगे।

In conclusion, the best white PVC material is a remarkable choice for various applications owing to its durability, aesthetic appeal, low maintenance requirements, and cost-effectiveness. As industries continue to evolve and prioritize sustainability, the demand for high-quality PVC materials is likely to rise. Whether you are involved in construction, manufacturing, or any other sector that requires reliable materials, white PVC stands out as a premier choice embodying quality and efficiency. Investing in high-grade white PVC not only enhances the overall quality of products but also contributes to sustainable practices, benefiting both consumers and the environment alike.